Description

Although most sudden cardiac arrests don’t happen in extreme environments some do. The HeartStart FRx is designed to work where rescuers may have to go to. In the rain, onboard aircraft, on metal surfaces or in industrial areas. (For details see:Technical data sheet) The FRx withstands jetting water, loads up to 250Kg and 1-metre drops to a concrete floor. It is also dust protected. HeartStart FRx is built with the knowledge of an installed base of over 600,000 HeartStart AED’s (September 2009). In the years since 1997 and the introduction of Heartstart FR, the HeartStart family of AED products including also FR2 and HS1 has been sold in numbers second to none. The continued performance through the years and the quality of these devices stand out in the AED industry. For many leading organisations around Australia HeartStart defibrillators are their AED of choice. HeartStart FRx includes the features proven in the field by the HeartStart family and has important new improvements making the FRx the partner needed during the critical moments.

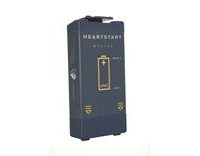

Internal self testing is key to readiness in infrequently used products. HeartStart FRx incorporates daily, weekly and monthly self testing including a pads connection and integrity test to make sure everything functions when needed. HeartStart FRx requires no regular or contractual technical maintenance programs. All vital functions are tested in the internal self test program including full energy charge/discharge. A brief visual inspection confirms whether the FRx is functional or not. The blinking green status indicator is the ”ready” signal confirming all is well. Otherwise the FRx will produce an audio signal to notify that inspection is required. With the FRx in standby mode maintenance is simply visual inspection and replacement of consumables such as pads (every two years) and battery (every 4 years)